Expediting the Production Process without Sacrificing Quality or Precision

In any competitive market, all parties, no matter where they may be engaged in the supply chain, are always looking for an edge to help improve revenues, profitability, and/or market share. From materials suppliers to manufacturers to logistics to the end vendors. This often means finding ways to use time, money, and resources as efficiently as possible.

In any competitive market, all parties, no matter where they may be engaged in the supply chain, are always looking for an edge to help improve revenues, profitability, and/or market share. From materials suppliers to manufacturers to logistics to the end vendors. This often means finding ways to use time, money, and resources as efficiently as possible.

Within the precision manufacturing sector, the challenge lies in the implementation of such efficiencies without cutting corners, so to speak, to achieve any desired financial outcomes; sacrificing quality and/or accuracy/precision to save time and money is merely a short-term or band-aid-type action that will undoubtedly have dire long-term consequences.

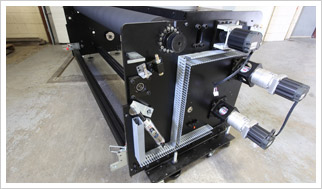

One solution for manufacturers may be the mechanical assembly services offered by Noble Precision. To expedite the production process, and hence save time and money, clients in the industrial or commercial equipment sectors may opt to have Noble Precision proceed with the assembly phase once we have completed the precision manufacturing of related parts and components.

By engaging the mechanical assembly services provided by the team at Noble Precision. Clients can realize several benefits/savings from the perspectives of time, costs, and/or use of internal resources:

- Fewer intermediate steps, therefore faster time to market

- Assembly done by staff with explicit knowledge of design/parts

- On-site availability of all requisite trades and associated expertise

- Consistency in production – design, manufacture, assembly, testing

These benefits are in addition to the accuracy and high tolerances achieved with the parts design and manufacturing capabilities made available to all clients through our state-of-the-art 5-axis simultaneous CNC machines and related CAD/CAM software.

Expertise in Mechanical Assemblies with Varying Degrees of Complexity

Mechanical assembly requires skilled engineering techniques or processes to ensure that the work is completed in a time-efficient, cost-effective, and, most importantly, correct fashion. At Noble Precision, our team of experts can capably assemble commercial and industrial equipment of varying complexity. Including pieces that may contain such elements as:

- Motors

- Pistons

- Turbines

- Hydraulics

- Electronics

- Pneumatics

- Wiring/Cabling

For more information regarding our mechanical assembly services, call Noble Precision at 416-938-6455 or contact us to arrange a no-obligation consultation on how we can assist in offering time-saving and cost-saving support for your equipment manufacturing needs.